Located in the heart of the Yangtze River Delta economic region, Changzhou neighbors Shanghai and serves as an integral part of the Suzhou-Wuxi-Changzhou Metropolitan Area. This unique geographical advantage fosters a thriving machinery manufacturing industry with notable enterprise clustering effects. However, as production scales continue to expand, energy consumption has soared dramatically, posing an urgent challenge for local machinery manufacturing enterprises to balance production with energy conservation and emission reduction while pursuing sustainable development.

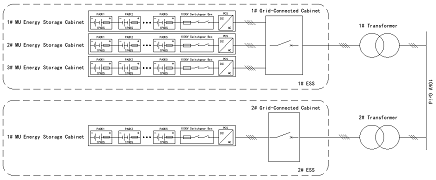

Addressing these pressing needs, TWS Anhui has teamed up with a renowned local gear manufacturing enterprise to successfully deploy a 420 kW/860 kWh energy storage project, which was recently connected to the grid and put into operation. Occupying only 5 square meters, the project comprises four TWS 215 kWh MU P-series liquid-cooling energy storage cabinets and a grid-connected cabinet. It is projected to enhance the consumption of clean energy by approximately 670,000 kWh and reduce carbon emissions by 301 tons annually, thereby providing robust support for the energy structure optimization as well as the energy conservation and emissions reduction of the machinery manufacturing enterprise.

TWS Anhui’s dedicated one-stop service team ensures the high-quality completion of the project from design, procurement, and construction to maintenance. Based on pre-project site surveys, the team tailored a solution with two energy storage sub-systems to precisely match user requirements and minimize initial investment costs.

Integrated with solar photovoltaic systems, the project adopts a mode of self-consumption and surplus injecting to the grid to optimize energy utilization. Leveraging the latest electricity tariff policies in Jiangsu Province, the project achieves a highly efficient operating mode of three-cycle-charging and three-cycle-discharging daily. By precisely executing peak-shaving and valley-filling strategies, the project is expected to generate a daily revenue of up to CNY 1,671, meaning a monthly revenue of CNY 50,130. Upon completion and grid connection, the project will alleviate frequent power outages and supply restrictions faced by machinery manufacturing enterprises during peak summer demand periods. It not only effectively balances electricity loads, ensuring stable production operations, but also reduces energy costs resulting from peak-valley tariff differences, promoting the widespread adoption of green energy and advancing energy-saving emission reduction goals, thereby facilitating corporate’s sustainable development.

Green transformation is the inevitable path for enterprise development. The successful implementation of this project not only invigorates local machinery manufacturing enterprises but also serves as a model for numerous enterprises exploring green development paths. Looking ahead, TWS Anhui will closely align with market demands, continuously optimize its product portfolio and service system, and actively explore diversified business models. With more comprehensive and professional product solutions and energy management services, TWS Anhui will continue to support on the green and low-carbon transformation of machinery manufacturing's energy structure, collaborating with partners from all sectors to advance towards carbon peaking and carbon neutrality goals, contributing positively to the construction of a green, low-carbon, and circular economy.